JLF Pro® is :

- 40 years of recognised expertise in risk prevention for professionals

- 40 years of commitment to a quality approach (ISO 9001: 2015 certification) and 10 years of commitment to a CSR approach (Ecovadis 2024 Evaluation: Platinum Medal)

- Insoles, work socks and PPE cleaning products specifically designed for professionals, in compliance with the latest standards.

- Work gloves renowned for their comfort and resistance

- Immediate availability of all our products

- Recognised support and expertise from our sales team

In addition to its solutions, JLF Pro® is expanding internationally and joining the major regulatory committees in its sector… to become a key player in occupational risk prevention. This recognition would not be possible without the team that makes it up: people who are experts in their respective fields, who work together to design your protection, and who like to do it with perfection !

Our first insole for industry

Launch of insoles specially designed and adapted for safety footwear, meeting the exacting standards of this sector.

Exclusive S3F® process to address hygiene issues

Sweating, skin fungus, hot and humid environments… There are no comprehensive statistics on these types of foot problems, but one thing is certain: it is important to protect against these types of bacteria in safety shoes to avoid discomfort and pain. JLF Pro® has thus developed the exclusive S3F® solution to prevent development of odours and growth of the bacteria and fungi that cause athlete’s foot.

New industrial site in Villebois-Lavalette in Charentes.

Creation of the JLF Pro® brand, for the professional world

The JLF Pro® brand is created so that wearers of safety shoes can recognise the products that best meet their needs. The entire JLF Pro® range has been designed and developed in collaboration with recognised podiatrists and specialists and meets the current standards.

First cushioning sole with Vibracut® technology

To provide better support within the shoe, the R&D of Groupe JLF develops products adapted to foot anatomy, in third-generation materials with excellent cushioning properties. Thanks to additional cushioning, JLF PRO offers insoles that limit pain and provide comfort in work shoes.

1st insole to prevent MSD*

JLF Pro® creates the first insole designed to limit from musculoskeletal disorders.

JLF Pro® insoles become antistatic

New packaging

JLF PRO has created explanatory packaging to make it easier for users to choose the product best suited to their needs at self-service sales.

Certified CSR approach (annual Ecocert audit)

Groupe JLF has always integrated social, environmental and economic concerns into its activities with stakeholders. In its quest for continuous improvement, Groupe JLF is going one step further by having its CSR approach assessed and certified.

Launch of the first JLF Pro® website

JLF Pro® has set up a new website to make your searches and information requests easier. Just one click gives you access to the advice of our experts, who offer adapted and personalised solutions to each problem encountered.

Launch of the JLF Pro® protective glove range

Thanks to its expertise in the textile industry and in risk prevention, the brand is taking on a new challenge with hand protection. As proof of its commitment to producing high-performance products, JLF Pro® has brought in an industry-recognised expert with more than 15 years’ experience in the field to head up this new range.

40 years of expertise. Thank you!

Even more sustainable products (recycled materials, durability test)

In the spirit of its CSR approach, certified in 2015, JLF Pro® continues to innovate and now offers products made largely from recycled materials and tests its products for greater durability over time.

New product and new communication materials

With SafetyPlus the benchmark in its category, JLF Pro has created Safety Warm to meet a frequent user need: combining warmth and comfort. Its plus point : its antistatic properties.

In line with current trends, such as the new ISO standard recommending the use of antistatic socks with footwear of the same type, JLF Pro is taking the lead and adapting its products accordingly.

This innovative approach is accompanied by the development of new communication tools, including a new website and merchandising solutions for the brand’s retailers.

JLF Pro awarded EcoVadis Platinum certification

In 2024, JLF Pro reached a new milestone in its CSR commitment by obtaining the prestigious EcoVadis Platinum certification! This distinction, which places us among the top 1% of the most responsible companies, rewards our concrete actions in favour of the environment, ethical practices and sustainable purchasing. This recognition reflects our determination to innovate for a more sustainable future. Find out how we integrate these values into the heart of our strategy and our products.

💡 Want to find out more about our commitment? Read our full article in the Learn & discover tab.

New JLF PRO's customisable product for comfort and performance

JLF Pro launches the BODY ADAPT insole, a revolution in workplace comfort.

Designed to adapt to the morphology of each user and the requirements of their workstation, the BODY ADAPT offers :

Total customisation with interchangeable inserts in the forefoot (rebound effect or cushioning) and heel (three levels of absorption depending on weight).

Advanced technology with the PORON® Comfort insert that reduces shock and vibration, improving protection for the joints and spine, and an eco-friendly approach: PU foam made from 80% recycled materials.

An inclusive and upgradeable product: all inserts are included, allowing easy adaptation in the event of a change of position and which adapts to the worker’s weight and height.

💡Want to find out more and discover the product sheet? go here -> Insoles Body Adapt

Our team of committed and invested experts

Our factories in France

We are very proud to have always tried to support the local economy by prioritising French or European manufacturing wherever possible. Today, most of our insoles and cleaning products are made in our factories in France.

Our factory in Villebois-Lavalette

Our cleaning products factory in the Loire

Quality requirements, continuous improvement, social responsibility

Factory audit

- Our factories based in France have been audited, as have those of our reliable partners selected according to their reliability, competence and various certifications (BSCI, SEDEX, ICS, AQF etc).

Quality control

- Our products not only meet all applicable standards and regulations, but are also extensively tested by independent laboratories to ensure durability, strength and efficiency.

- During shipment and delivery, our products are double-checked by independent organisations and by our teams.

Continuous feedback

- Although JLF Pro® staff are recognised for their expertise, we believe that it is those who use and those who prevent who best know their needs. For this reason, JLF Pro has always maintained a relationship of trust with you to ensure continuous feedback on use of our products and to design equipment that always most closely matches your real needs.

Precise traceability

- Transparency is a principle on which JLF Pro® never compromises. Providing access to all information is a matter of course for us, which is why we have full traceability (registered batch number) and are trained in quality portals and current product platforms.

JLF Pro®, a committed player in the field of occupational risk prevention

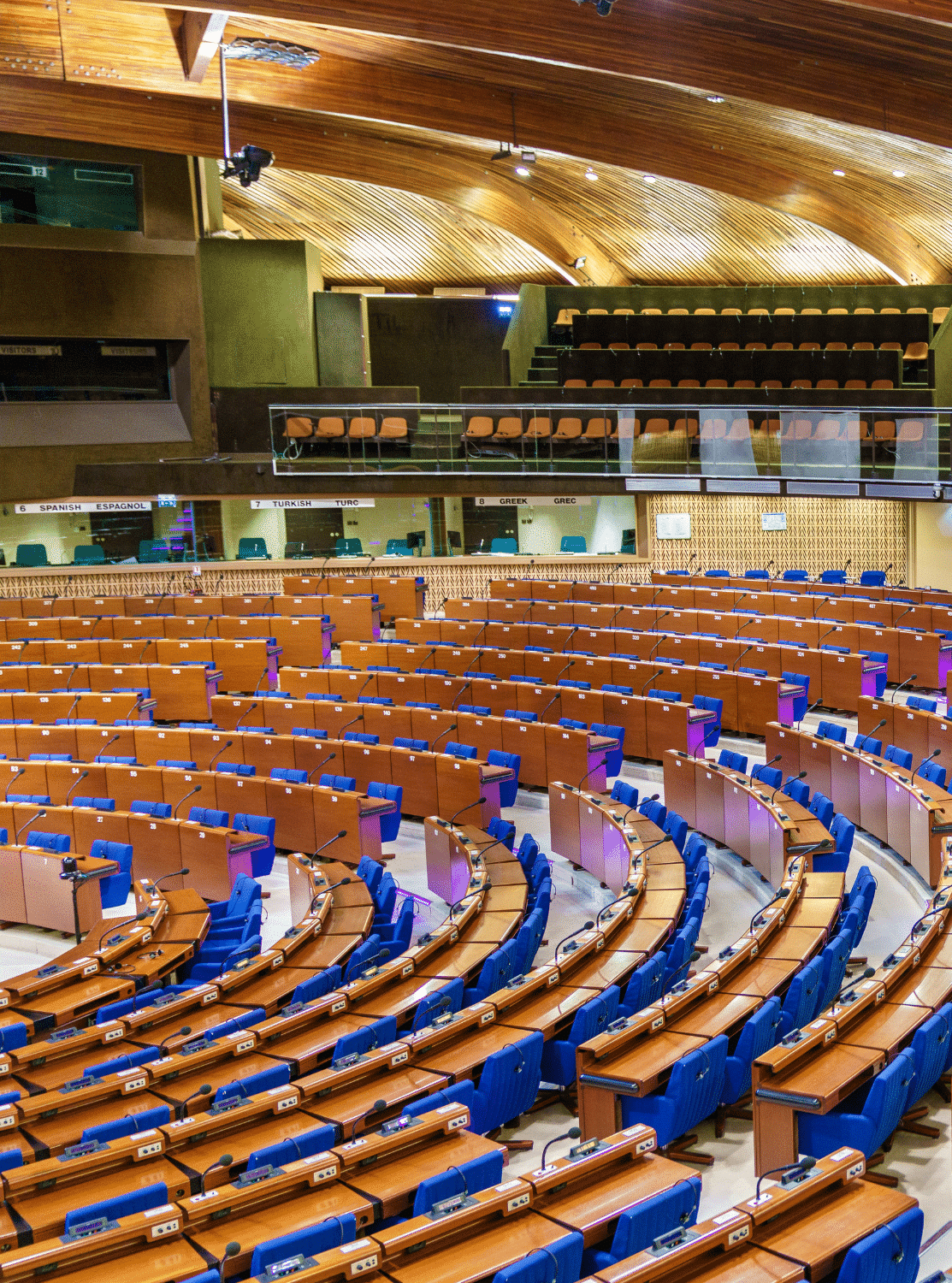

Active member of the National Prevention Market Actors Syndicate

- Vice-Presidency of the Synamap Board of Directors. Active participation in commissions and working groups dedicated to advancing CSR issues, safety and comfort of users at work, standards and best practices.

- Active participation in commissions and working groups dedicated to advancing CSR issues, safety and comfort of users at work, standards and best practices.

ISO, CEN, AFNOR

- Active member of international, regional and national standards committees for safety footwear and work shoes.

- Active member of the expert committee for Fire Fighter PPE standards

Member of the French Technical Centre for Leather

- Active collaboration in preventive communication campaigns.

- Active participation in commissions and working groups.